The University of Sheffield Rail Group recently demonstrated innovative laser cladding technology aimed at enhancing railway infrastructure repairs. On November 7, 2023, industry partners gathered at British Steel to witness field demonstrations showcasing how this additive manufacturing technique can effectively repair railway components while providing improved wear resistance.

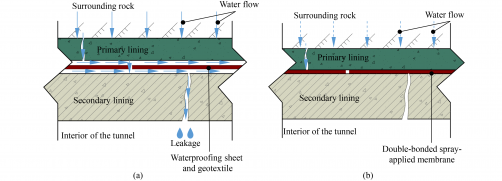

Laser cladding involves the application of powdered materials onto a substrate, which are then melted and bonded through a high-powered laser. This method not only repairs existing railway infrastructure but also significantly extends the lifespan of crucial components. The demonstration highlighted the potential for reduced downtime and lower maintenance costs, factors that are essential for maintaining the efficiency of railway systems.

Dr. John Smith, a leading researcher at the University of Sheffield, emphasized the importance of this technology in modern railway maintenance. “Our goal is to revolutionize the way we approach repairs,” he stated. “Laser cladding offers a sustainable solution that minimizes waste and maximizes the durability of rail components.”

During the event, participants observed live demonstrations that illustrated the practical application of laser cladding on various railway elements. The technology has been developed with input from industry partners, ensuring that it meets the specific needs of railway operators.

The potential economic benefits of adopting laser cladding technology are significant. According to industry estimates, implementing this method could reduce repair costs by up to 30%, while also decreasing the frequency of repairs needed. This not only saves money but also enhances safety and reliability within the railway network.

The demonstrations at British Steel marked a crucial step in the collaboration between academia and industry. Stakeholders from various sectors of the railway industry attended, including representatives from engineering firms, railway operators, and maintenance service providers. The feedback received from attendees was overwhelmingly positive, with many expressing enthusiasm about the prospects of integrating this technology into their operations.

As the railway industry faces increasing pressure to improve efficiency and sustainability, innovations like laser cladding are becoming more relevant. The University of Sheffield Rail Group aims to continue its research and development efforts, focusing on refining the technology for broader application across the railway sector.

In conclusion, the successful demonstration of laser cladding technology at British Steel exemplifies the collaborative efforts between the University of Sheffield and industry partners to enhance railway repair processes. This technology not only promises to improve the durability of railway infrastructure but also offers significant cost savings, paving the way for more sustainable railway operations in the future.