A team of researchers from the Massachusetts Institute of Technology (MIT) has created a new material that can morph into various three-dimensional structures with a simple pull of a string. This innovative development draws inspiration from the Japanese paper art technique known as kirigami, which involves cutting and folding paper to create intricate designs. The findings were detailed in a recent paper published in the ACM Transactions on Graphics.

Transforming Design into Reality

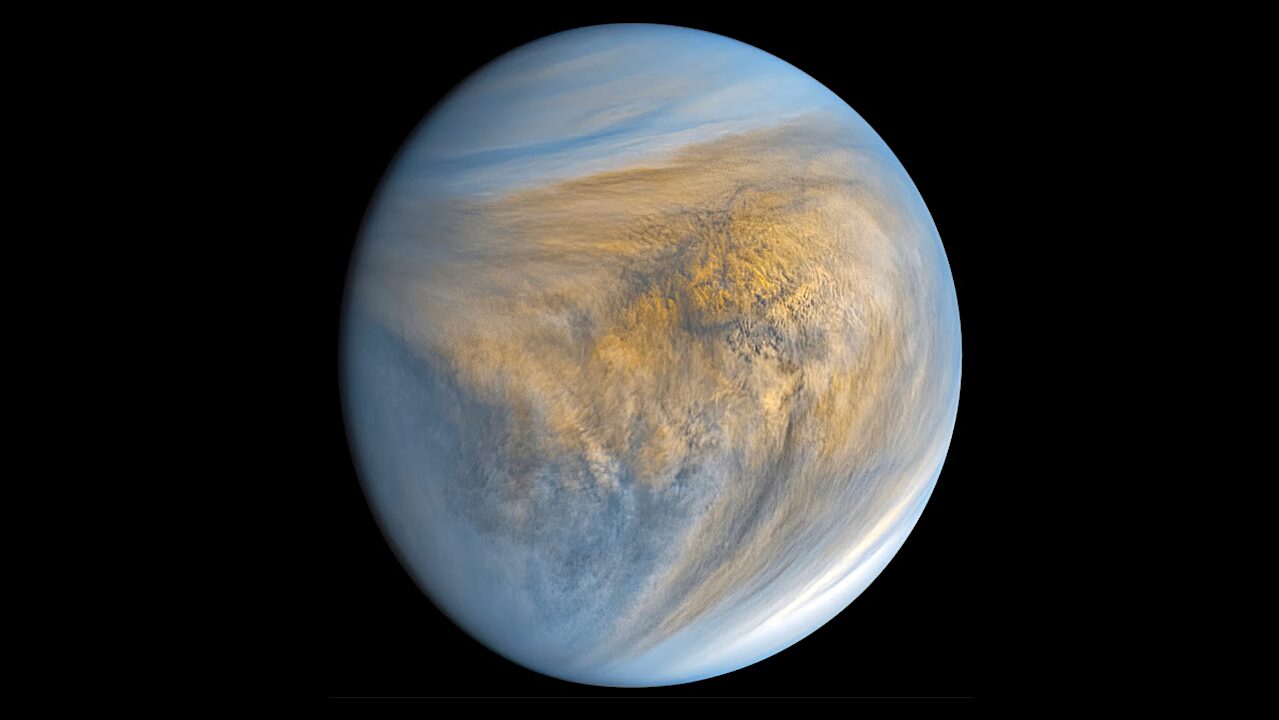

At first glance, the material appears as a flat, tiled pattern, lacking any extraordinary qualities. However, the true potential of this material is revealed when users pull a small string attached to it. The grid rapidly transforms into the intended 3D shape, demonstrating remarkable versatility. The researchers envision a wide range of applications for this technology, including transportable medical devices, foldable robots, and even modular habitats for potential use on Mars.

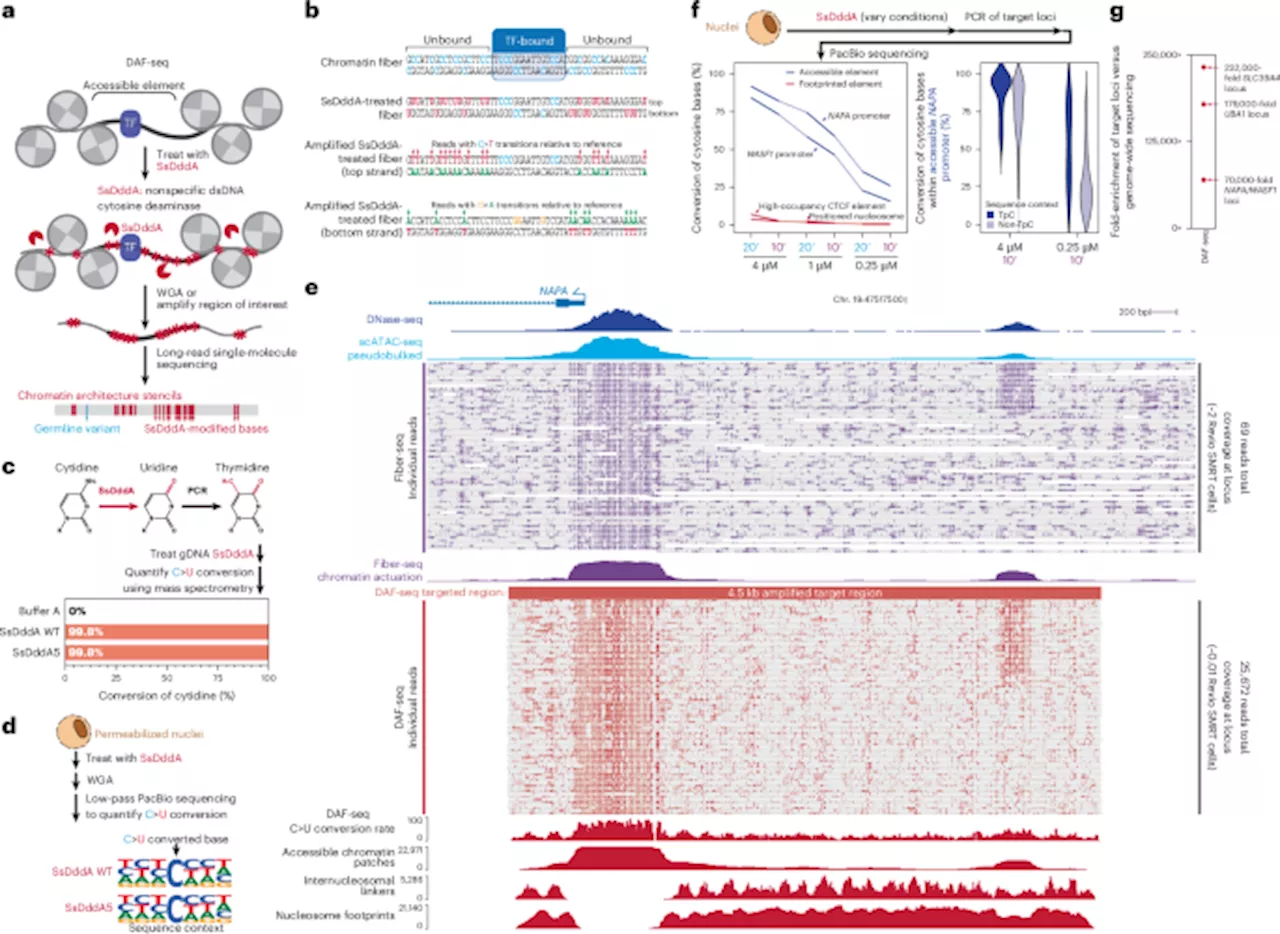

To achieve this transformation, the research team developed a unique algorithm that translates user-provided 3D designs into a flat grid of quadrilateral tiles. This approach emulates the techniques used by kirigami artists, who cut and manipulate paper to impart specific properties to their creations. The mechanism at work involves an auxetic mechanism, which causes the structure to become thicker when stretched and thinner when compressed. The algorithm calculates the optimal string path to minimize friction and ensure a smooth transition from the flat design to the 3D structure.

Real-World Applications and Future Potential

Lead author Akib Zaman, a graduate student at MIT, emphasized the user-friendly nature of the system. “All they have to do is input their design, and our algorithm automatically takes care of the rest,” he explained. Following several simulations, the team successfully designed various practical objects, including medical tools like splints and posture correctors, as well as igloo-like structures.

The algorithm’s flexibility extends to different fabrication methods. For instance, the researchers utilized laser-cut plywood boxes to create a fully deployable, human-sized chair, which proved to be functional when tested. While the study acknowledges that larger architectural projects may present “scale-specific engineering challenges,” the ease of use and accessibility of this novel method has inspired the team to explore additional applications.

Zaman expressed hope that this technique will enable the creation of an array of deployable structures. As the researchers continue to refine their approach, they are excited about the potential to address existing challenges and expand the range of structures that can be produced using this groundbreaking material.