In a significant advancement for tunnel engineering, a team of researchers has developed a novel waterproof-drainage system designed to combat water leakage, a pervasive issue that compromises tunnel safety and longevity. The study, titled “A Novel Tunnel Waterproof-Drainage System Based on Double-Bonded Waterproofing Materials and Its Seepage Characteristics,” was spearheaded by experts from Central South University, PowerChina ZhongNan Engineering Corporation Limited, Beijing Oriental Yuhong Waterproof Technology Co. Ltd., and Shenzhen University.

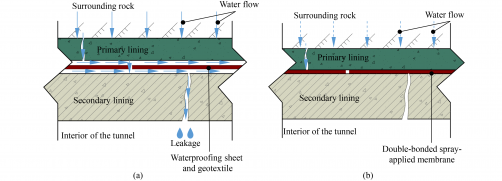

Traditional waterproofing methods often rely on non-bonded waterproof sheets, which allow groundwater to flow between layers, leading to potential leaks and structural damage. The innovative approach of using double-bonded spray membrane waterproofing materials presents a solution. These materials not only provide robust waterproofing but also enhance load-bearing capabilities. However, their design complicates the use of conventional drainage methods in drainage-type tunnels.

Innovative Design and Key Components

The research team, including Xiaohe SUN and Chenghua SHI, proposed a system based on the concept of “localized drainage and pressure reduction.” This system features four essential components: a waterproof system, an upper circumferential drainage system, a bottom circumferential drainage system, and a longitudinal drainage system.

The waterproof system integrates a double-bonded spray membrane situated between the primary and secondary linings, with the exception of the arch section. The upper circumferential drainage system employs plastic drainage sheets positioned between the membrane and primary lining, along with transversal guide pipes that funnel groundwater to longitudinal pipes, ultimately directing it to a central ditch.

Similarly, the bottom circumferential drainage system consists of bottom drainage blind pipes that collect groundwater from surrounding rock, aided by vertical guide pipes that lead water to the central ditch. The longitudinal drainage system completes the setup with longitudinal blind pipes, side ditches, and a central ditch, creating a comprehensive network for discharging groundwater outside the tunnel.

Impact on Water Pressure and Adaptability

To evaluate the system’s effectiveness, the researchers conducted numerical simulations focusing on steady-state seepage analysis. The results indicated that the water pressure exerted on the secondary lining displayed distinctive distributions, characterized as circumferentially “mushroom-shaped” and longitudinally “wave-shaped.” The maximum secondary lining water pressure recorded was 0.6 MPa, which is 65% lower than that of fully encapsulated waterproofing systems (1.7 MPa) and 30% lower than traditional drainage systems (0.86 MPa).

Moreover, the applicability analysis revealed that this innovative system reduces static water pressure by at least 40% across various groundwater environments. In cases involving ultra-low permeability strata (with a permeability of 10−7 m/s), the reduction in water pressure could be as high as 85%. The system displays impressive adaptability: bottom blind pipes are most effective in high-permeability rock, while upper drainage sheets excel in low-permeability conditions.

The findings of this study not only highlight the potential for enhanced tunnel safety and durability but also pave the way for more effective applications of waterproofing technologies in tunnel engineering. The full text of the study is available at https://doi.org/10.1007/s11709-024-1100-4.