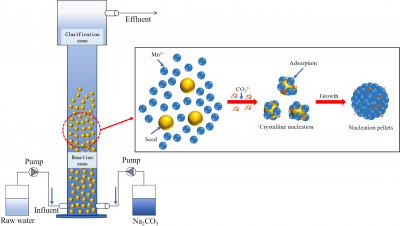

A recent study has unveiled an innovative method for recovering manganese ions from hydrometallurgical tailings water, showcasing the potential of the nucleation crystallization pelleting process. This technique promises to enhance resource recovery while significantly reducing environmental impacts associated with waste disposal.

The research highlights the efficiency of this process, demonstrating its capability to recover high concentrations of manganese ions from tailings water. With growing concerns over resource wastage in hydrometallurgical operations, this study, conducted in September 2023, provides a practical solution that could transform the mining industry’s approach to waste management.

Significance of the Findings

Manganese is a critical element used in various industrial applications, including steel production and battery manufacturing. The conventional methods of extracting manganese often result in substantial waste and environmental degradation. The newly developed process addresses these issues by allowing for the recovery of manganese from sources that would otherwise be discarded.

According to the researchers, the nucleation crystallization pelleting process not only increases recovery rates but also minimizes the ecological footprint of mining operations. By focusing on high-concentration manganese ion recovery, this method presents a dual benefit of economic efficiency and environmental sustainability.

The implications of this study extend beyond theoretical applications. The practical applicability of the nucleation crystallization pelleting process indicates that it can be integrated into existing hydrometallurgical operations, thus promoting a more sustainable approach to resource extraction. As industries seek to reduce their environmental impact, this method offers a promising direction.

Next Steps for Implementation

To facilitate the adoption of this innovative technology, further research and development will be essential. Future studies will likely focus on scaling the process for industrial use, as well as assessing its long-term effects on the environment. Collaborations between academic institutions and industry stakeholders may accelerate the integration of this process into commercial operations.

The findings of this study are a step toward enhancing resource efficiency in the mining sector. By leveraging advanced technologies like the nucleation crystallization pelleting process, industries can reduce waste, improve recovery rates, and contribute to a more sustainable future. This approach has the potential to redefine how manganese and other critical minerals are sourced, aligning economic interests with environmental stewardship.